Introduction

SPIRAMATIC VSA Fine Drum Screens are used in both municipal and industrial applications, as well as for the pretreatment in MBR plants. The machine screens, washes, conveys, and dewaters screenings all in one unit, thus eliminating the need for multiple pieces of equipment.

Ideal solution for MBR process

High screenings capture efficiency

Proprietary face seal design eliminates bypass of hair and other fibrous materials

Technical Specs

Description

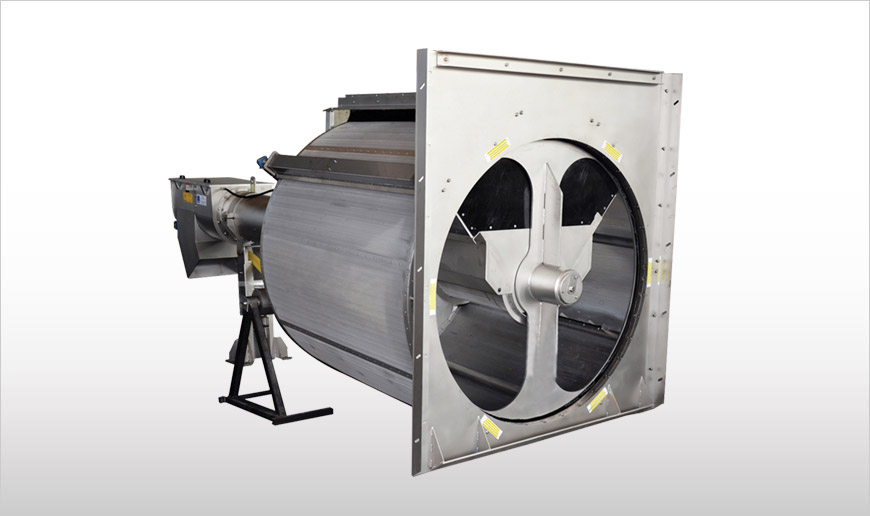

SPIRAMATIC VSA Fine Drum Screens consist of a rotating drum screen, a conveyor screw, and a compaction zone. Depending on the application, the fine screen drum can be made up of a set of steel bars – in which case the distance between the bars determines the desired slot width – or of a perforated sheet filter. The cylindrically shaped drum can be placed inside a channel or a fabricated tank.

Function

SPIRAMATIC VSA Fine Drum Screens wash, convey and dewater waste water screenings all in one unit. They are designed to wash out organic matter from screenings. Both screen basket and dewatering zone are self-cleaning. Rotating around its axis, the cylindrical filter conveys the screenings to a loading hopper placed in the centre. A set of spray nozzles washes the filter during operation. A screw, placed inside the conveying pipe, with its top in the discharge hopper, conveys the screenings towards the following treatment stages during which organic substances are washed out. Subsequently, solids are compacted and dewatered in the compacting and drainage area. Finally, solids are discharged through an discharge chute into a container or compactor.

Features

- Filter mesh sizes for MBR pre-treatment:

- 1.0 – 1.5 – 2.0 – 3.0 mm round holes

- Filter mesh sizes (other than MBR use):

- 5.0 – 6.0 mm round holes

- 0.5 – 1.0 – 2.0 – 3.0 – 4.0 – 5.0 – 6.0 mm wedge wire

- Channel width: 600 ~ 3,000mm

- 35-degree incline angle

- Frame manufactured from 304 L / 316 L SS

- Spiral manufactured from special ST 52 steel, or 304 L / 316 L SS

Benefits

- Triple face seal for maximum capture efficiency of fine solids

- Spray bar installed on the outside of the screen basket, thus enabling optimum capture of small solids

- Cleaning brush fitted on the screen maintains screen surface clean

- Durable brush attached to the flighting on the auger trough sweeping even smallest solids into auger trough for removal

- Large, robust, self-lubricating bronze bushing (no lubrication pump or maintenance required)

- Low energy consumption and limited maintenance

Options

- Alternative screen types and sizes

- Available for both in-channel and in-tank application

- Alternative voltage and frequency

- Alternative degree of motor protection

- Control panel

Accessories

- Removable, sliding aluminium covers

- Fixed stainless steel covers

- Bagger

- Heating device